Structural Limitations: Too light to fly?

Besides maximum design weights, a minimum aircraft mass is also required. In order to certify the aircraft, it must comply with all requirements applied by the regulator.

The scope of these regulations includes a detailed description of handling qualities, structural loading conditions, and flight performance criteria which must be met at any weight belonging to the approved range.

In other words, during the certification process, the manufacturer must prove that the aircraft is controllable, complying with performance requirements, and withstands expected structural loading at all certified weights.

Minimum Flight Mass is the lowest weight at which compliance with all applicable requirements can be assured. It includes empty weight + standard equipment + 2 required crew members + full oil + Minimum Fuel*+ ballast**

*Minimum Fuel can be established by the manufacturer or computed as the quantity necessary for a 30-minute flight at METO power setting.

**Ballast weight is required to keep the center of mass position and total mass within the design requirements for safe handling characteristics.

If the aircraft is below that minimum, it might lose its controllability in case of engine failure or stress force exerted by a sudden gust that could exceed the structural strength limitation.

To sum it up, there is a Minimum Aircraft Mass at which the aircraft is allowed to fly. Whenever minimum weight cannot be reached by adding some PAYLOAD (for example for ferry flights), solid ballast or extra (unusable) fuel should be considered.

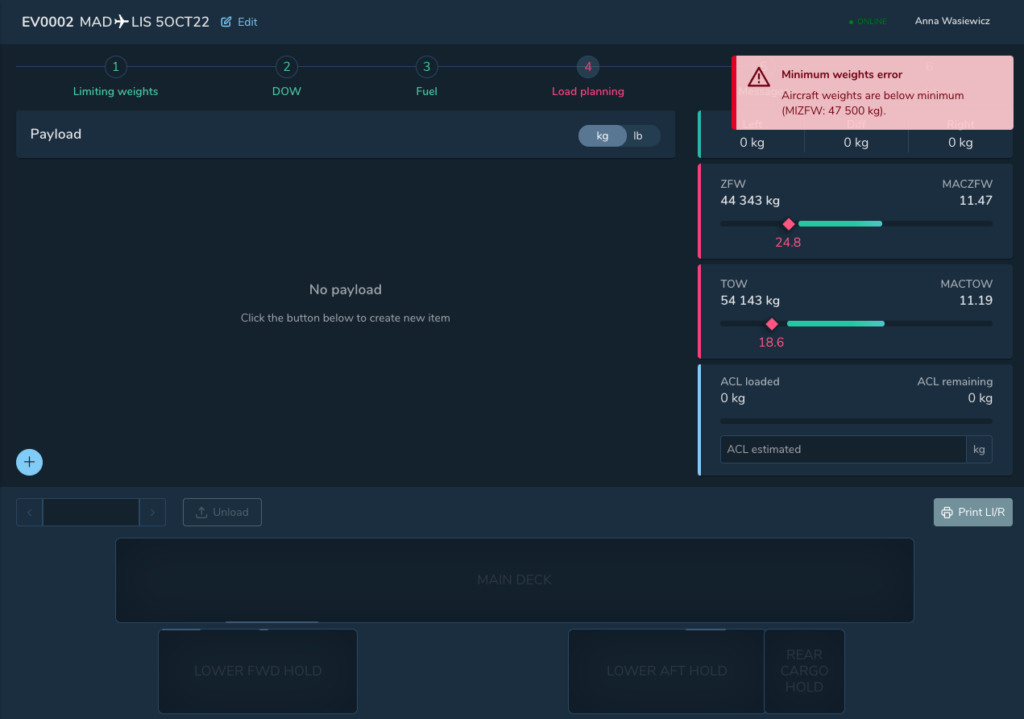

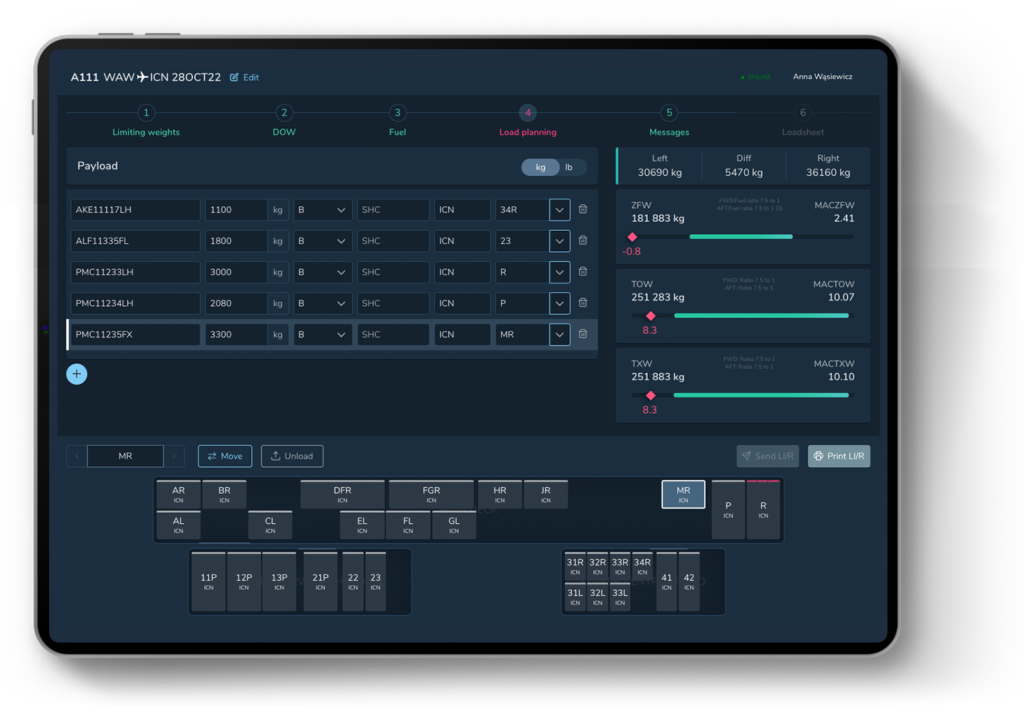

Evionica’s Weight and Balance solution monitors the actual aircraft mass for Take-off and Landing. The user gets a notification whenever at least one is lower than the minimum required for a flight. Additionally, previewing and sharing the Loadsheet document is blocked unless the issue is solved.